WILMINGTON, NC – October 2025 – Wilmington Rubber and Gasket Company, Inc. is proudly celebrating its 40th anniversary this October, marking four decades of providing reliable industrial solutions to customers in North Carolina, across the United States, and beyond.

Founded on October 1, 1985, by Denise and Howard Russell, Wilmington Rubber first opened with a focus on meeting the hose, gasket, and sealing needs of businesses in the Wilmington community. What started as a local operation has since grown into a company with a far-reaching footprint, with its products now serving customers across the United States and in select markets overseas.

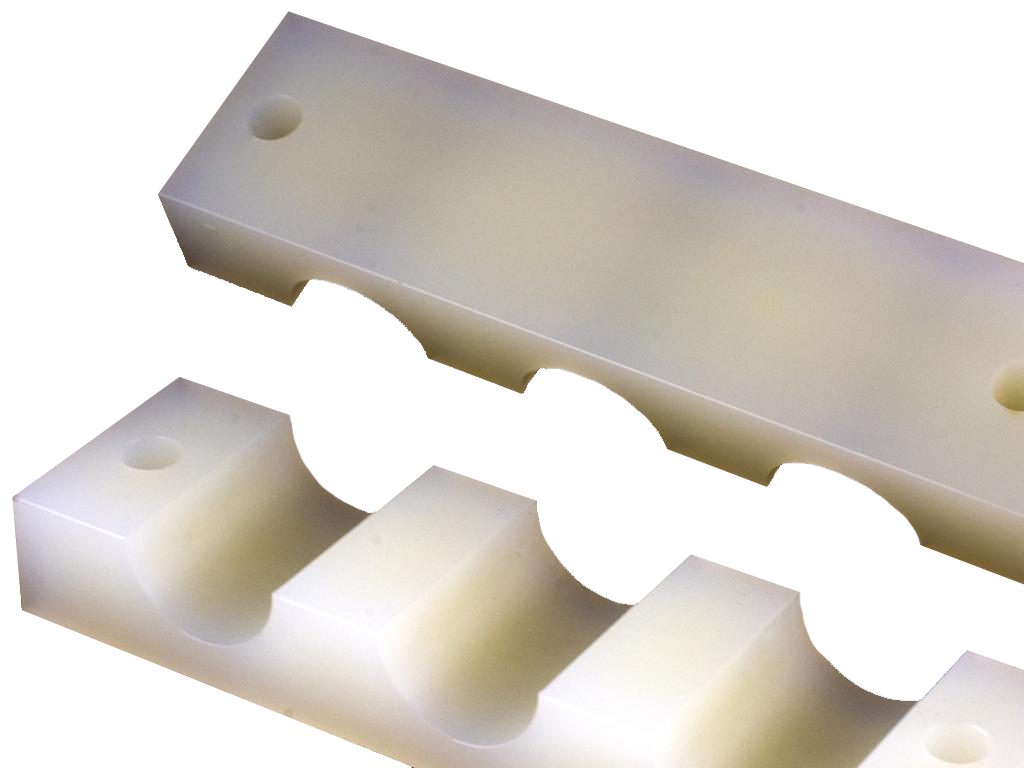

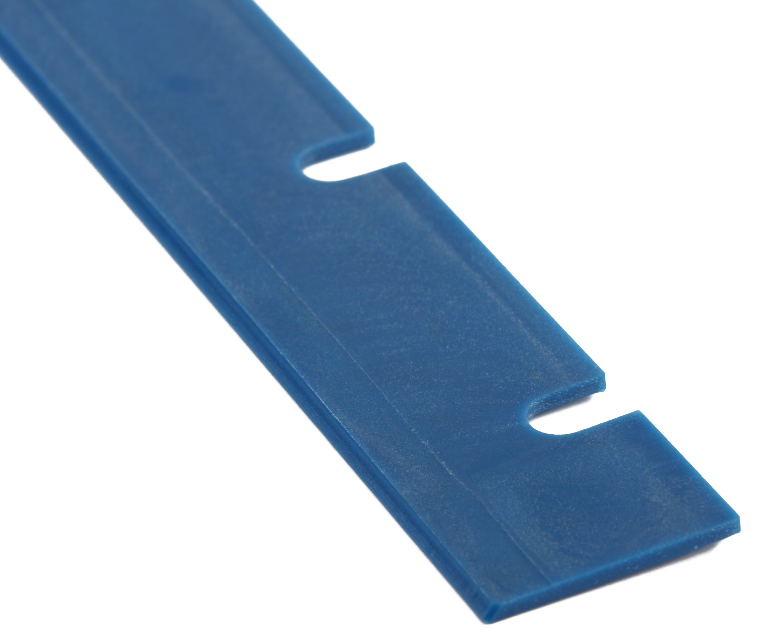

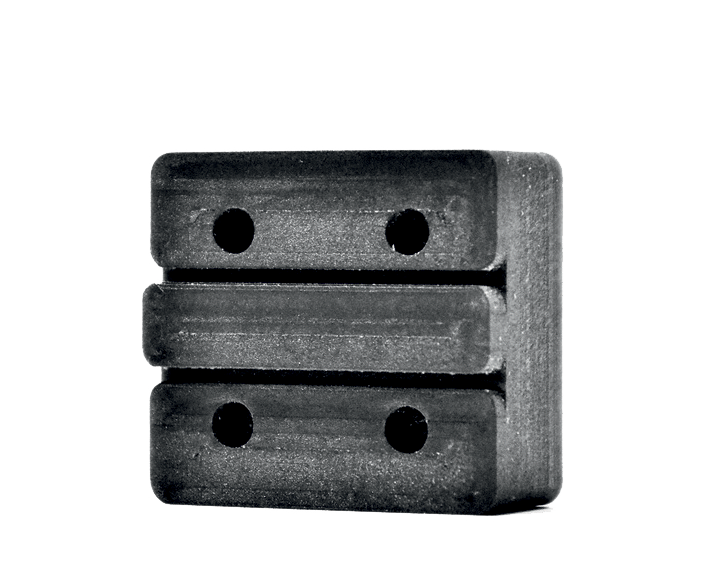

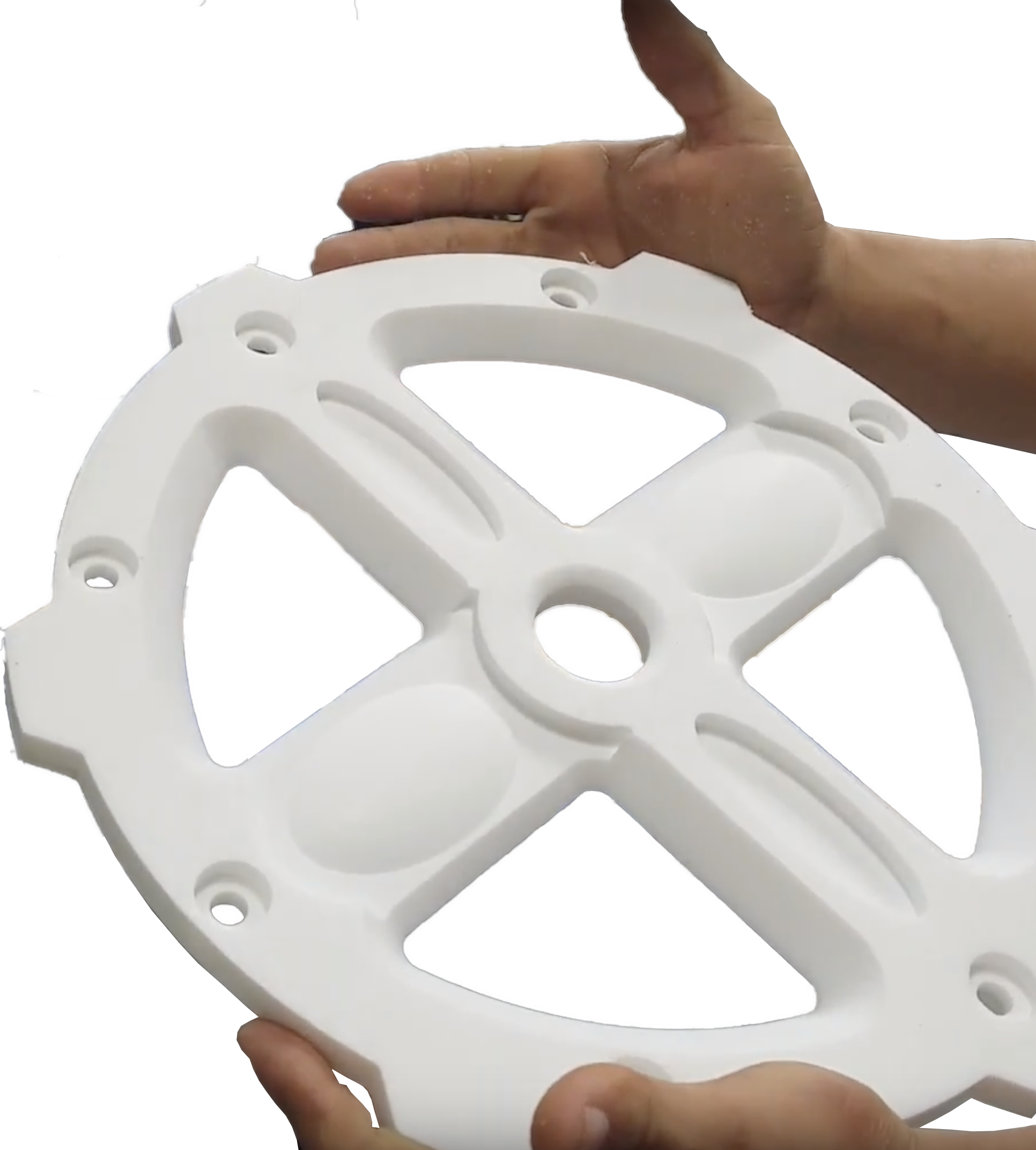

From the start, Wilmington Rubber’s success has been built on more than just supplying industrial parts—it has been driven by a commitment to solving customer challenges. By developing solutions to meet unique fluid sealing and conveyance needs, the company has grown and diversified its product lines and manufacturing capabilities far beyond what its founders initially imagined possible.

“When we first opened Wilmington Rubber, our goal was to serve our industrial community with quality products and dependable service,” said founders Denise and Howard Russell. “Forty years later, it’s humbling to see how far that vision has carried us. The relationships we’ve built with our customers and employees are what truly define our success.”

Wilmington Rubber became part of the Singer Industrial group in May 2025, joining a nationwide network of industrial solution providers. This partnership has expanded the company’s resources and market presence, while preserving the trusted, customer-focused service that has defined Wilmington Rubber since its beginning.

Today, Wilmington Rubber continues to be a reliable partner to a wide range of industries—including manufacturing, chemical processing, marine, food & beverage, energy, construction, and agriculture. From custom hose assemblies to gasket fabrication and beyond, Wilmington Rubber remains focused on innovation, quality, and customer satisfaction.

For more information about Wilmington Rubber, visit www.wilmingtonrubber.com.