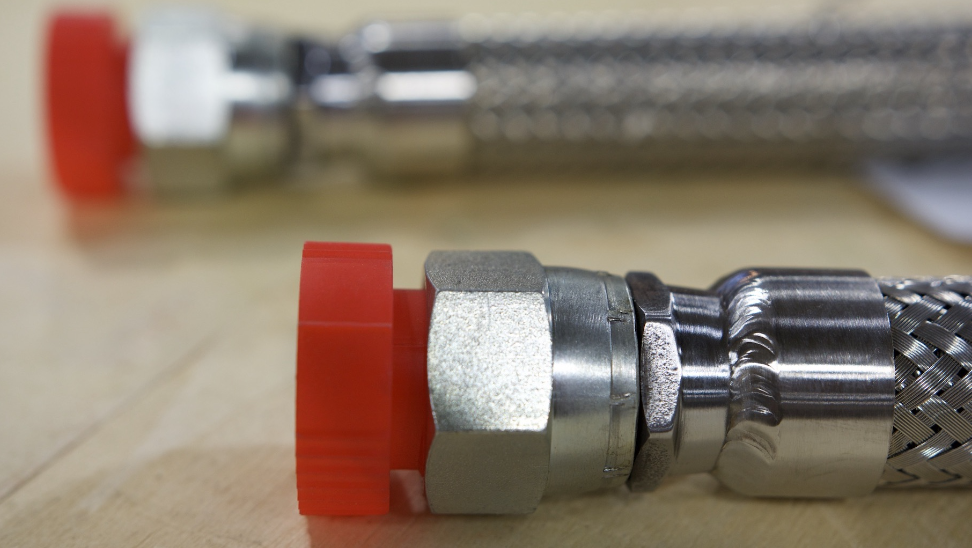

Metal Hose & Accessories

We inventory stainless steel core and braid hose and a variety of stainless steel weld-on fittings allowing us to weld a flexible metal hose in a short amount of time. We also stock metal Telfon-lined hoses and associated fittings for a number of diverse applications. We offer welding services for metal hose and that makes us your premier metal hose supplier. Please view our welding service page or CONNECT WITH US for more information.

We also offer industrial, hydraulic, and cleaning hose products.

From lightweight, flexible hose to the triple-braided heavy-duty hose for severe service, we can accommodate applications from the least to most demanding. Using different alloys, wall thicknesses, hose diameters, pitches and corrugation counts allows us to meet various temperature, pressure, movement, and corrosion resistance requirements.

Metal hoses range in size from ¼”- 24” and are available in 321 or 316L stainless steel with single or double layers of 304L or 316L braid. 700 Series is the exception with options for Monel™ 400, Hastelloy™ C276, Inconel™ 600, Inconel™ 625, Incoloy™ 825, AL-6XN™, and Bronze. These high nickel alloys offer increased corrosion resistance while bronze is often called for in HVAC applications. Other alloys are available upon request.

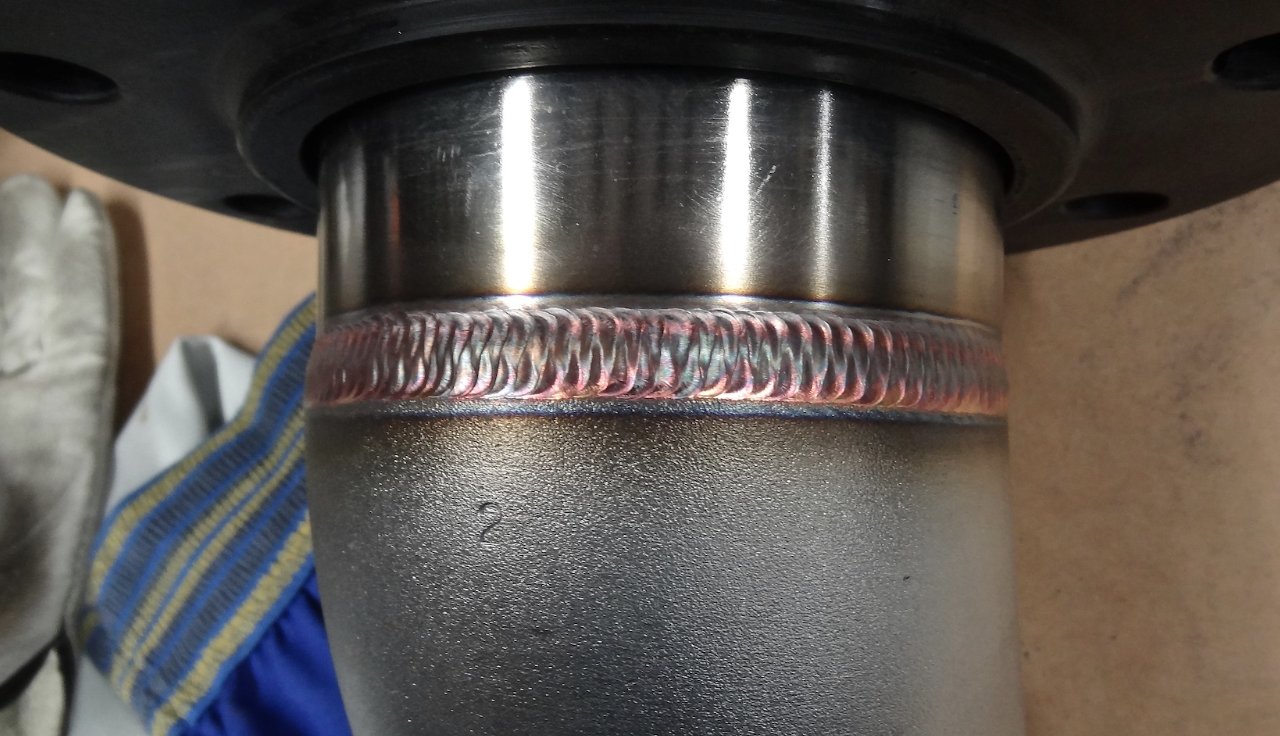

Beyond our line of signature metal hose and braid products, we design & manufacture expansion joints to offer a broad range of flexible piping solutions to customers across industries.

Expansion joints absorb movement and vibration in a piping system, which rotects adjacent piping and equipment from damage.

To make an expansion joint, we weld various end fittings on to a flexible bellows component. Relatively thin-walled tubing is used to form a single or multi-ply corrugated cylinder. In the expansion joint industry, these corrugations are called convolutions. This is the bellows component. Selecting the right alloy, wall thickness and convolution geometry allows for the design of a bellows that can meet or exceed the pressure and temperature requirements of adjacent piping.

The interplay between alloy, wall thickness and convolution geometry also determine how much movement an expansion joint can absorb.